XINMAO is your premier provider of advanced water bottling solutions.

Our cutting-edge technology and industry expertise ensure that we deliver efficient,high-quality bottling systems tailored to meet your customized needs.

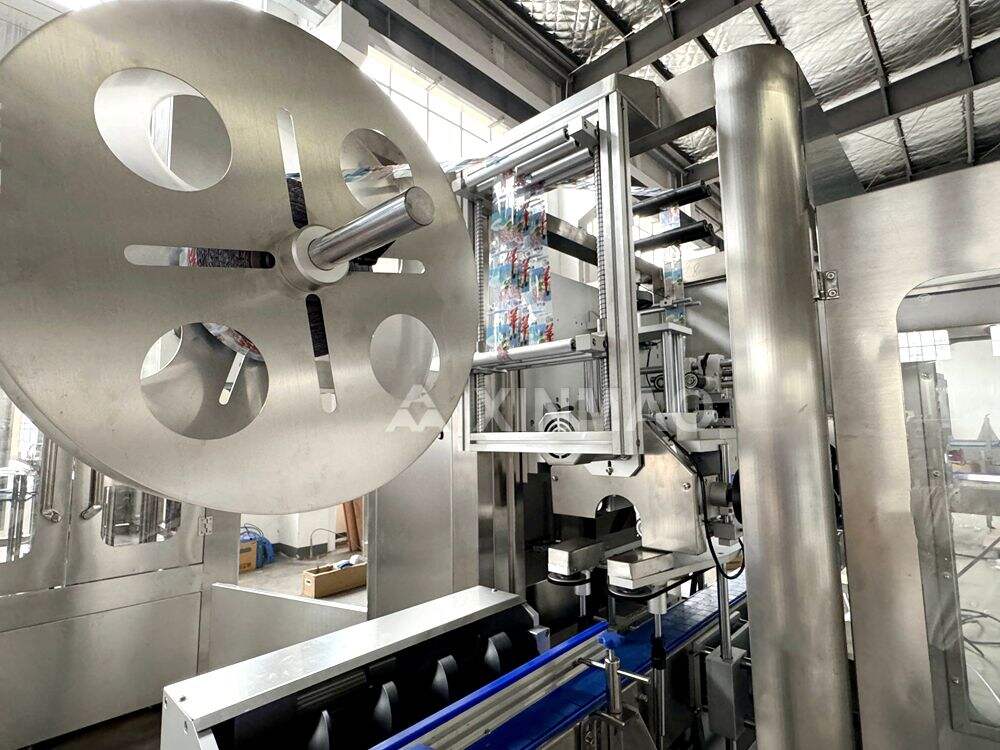

The sleeve labeling machine is double head mechanism to meet the requirements of casting label for bottle mouth and bottle body., a wide range of products, mainly suitable for a variety of container bottles, container cans, a variety of shapes and materials of shrink film packaging.

The machine adopts international advanced technology; cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body designated.This machine's structure is compact, and suitable for the production line of different direction and different height. The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; It is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

| Technical Parameter | |||||

| Model | XM-150 | XM-250 | XM-250D | XM-300 | XM-400 |

| Capacity | 150 bottles/min | 250 bottles/min | 250 bottles/min | 300 bottles/min | 400bottles/min |

| (On the base label length :500ml) | |||||

| Label heights | 30~250mm | 30~250mm | 30~250mm | 30~250mm | 30~250mm |

| Bottle diameter | 28~125mm | 28~125mm | 28~125mm | 28~125mm | 28~125mm |

| Thickness of label | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm | 0.03~0.13 mm |

| Label material | PVC/ PET | PVC/ PET | PVC/ PET | PVC/ PET | PVC/ PET |

| Machine weight | 550KG | 600KG | 700KG | 800KG | 950KG |

| Overall machine size (mm) | 2100x850x2100 | 2100x1100x2100 | 3200x 1200x2070 | 2600x 1100x2200 | 2600x 1100x2200 |

Automatic linear shrink sleece labeling machine is the advanced continous operation of the labeling machine. The labeling machine is mainly used for container labeling cylindrical, square or other special shape of detergents, beverages, mineral water, food etc. Labeling machine is control by PLC touch screen, all photo sensros are imported advanced configuration. The shrink labeling machine with high speed, high accuracy, stable performance, easy to operate and look elegant appearance.

Label Sleeve Host Display

1.Unique sleeve labeling method, using pressure sleeve labeling method.

2.The unique knife disc design can avoid changing the knife holder and change the knife quickly and easily.

3.Middle guide rod clamping system, fast mold changing speed, no need of any instrument.

Steam Shrink Tunnel

The purpose of this part is to separate the bottles to facilitate the labeling,it is fully automatic and high speed .

Improved Label Brush Down System

1.After the label is set, use the brush to reach the fixed label position.

2.Good elasticity, wear - resistant, not easy to damage, long service life.

3.Simple operation, short replacement time.

Bottle-separating Screw

This part is used to separate the bottles to be set at equal intervals and enter the bottle group.

Rack Group

Save the time of changing materials, the discharge is fed by a set of conveying roller reduction motors.

Touch Screen

The machine has been programmed with various programs, the touch screen issues commands, and the commands act.

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |