Automatic Juice Filling Machine is equipment used in fruit juice automatic hot filling operations, offering efficiency ,reliability and precision in the packaging of bottle juice products .suitable for various sizes and capacities.

Application : Fruit juice / tea drinks / energy drinks bottle hot filling line

Suitable for: PET containers

Bottle sizes:Within 2L

Filling system: Gravity hotfill

Filling speed: 2,000 - 24,000BPH (500ml)

Function :Rinsing Filling Capping Machine

The processing including washing filling capping are composed in one body of the machines ,the complete process also can include mixing and sterilization & homgenizer , Filling&capping ,Labeling ,Quality control ,and packaging system ,The famous brand components and control system is adopted to run machines automatically ,ensuring efficient , precision,and hygienic packaging of bottled beverage products.

Welded by SUS304. Product contact is SUS304 food grade;

·High-efficiency rinsing-nozzles can spray water to any part inside the bottle;

·Corrosion-resistant bearings from NSK or SKF;

·Mechanical valve filling, flow meter filling, weighing filling or laser positioning filling for choice;

·Centralized waste water discharging system;

·Centralized lubricating system;

·ABB main motor for better performance;

·Danfoss VFD system;

·French "ZALKIN" capping technology is used for higher performance;

·Constant capping torque is applied to avoid cap damage.

1. Water Treatment System

Water Treatment

Water purification system can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the raw water resource. It can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh drinking water standards, even standard of healthy mineral water.

Purify Process:

Raw water>Water pump>Silica sand filter>Active carbon filter>Sodium ion exchanger>High pressure pump>Reverse osmosis>Ozone generator>Water tank>Pure water

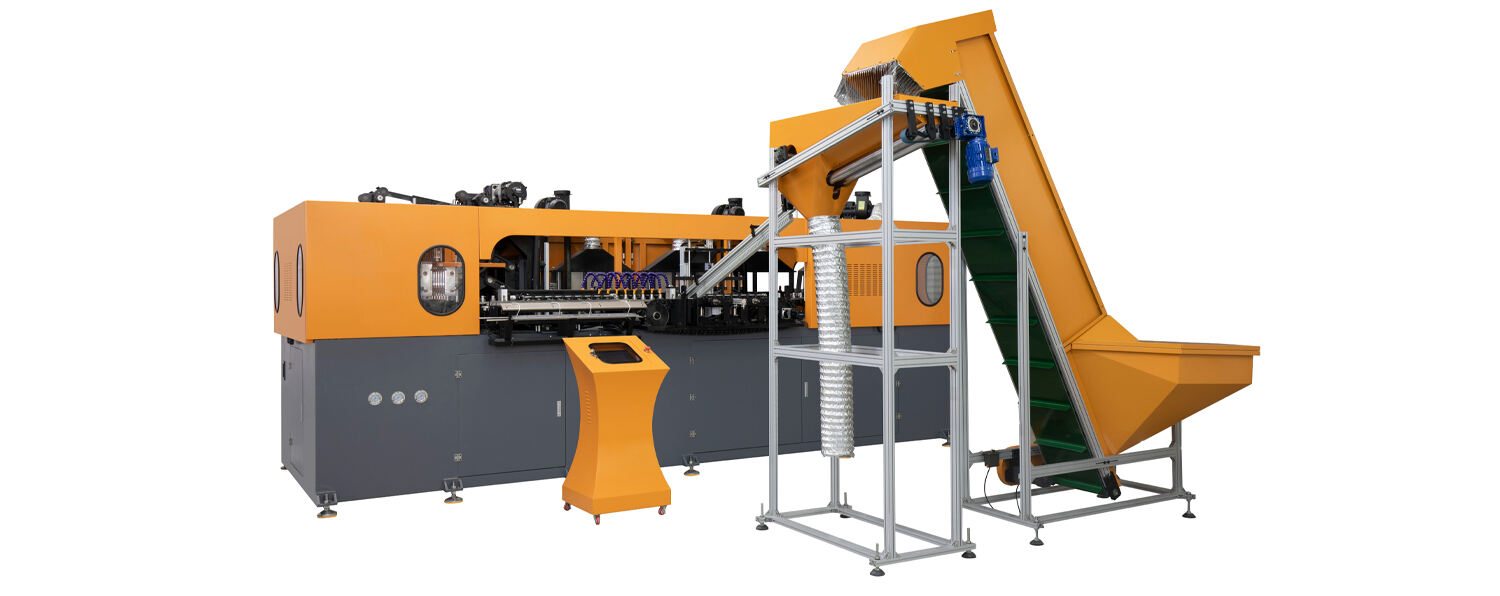

2.Blow Molding Machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing water bottles, soda bottles, cola bottles. Bottle shapes are all customized and can be adjusted according to your requirements.

Blowing process:

1) Preform inlet controlling

2) Bottle preform heating controlling

3) Blowing technology controlling

4) Bottle check and outlet

3.Mixing System:

The core function of the functional beverage preparation system is to accurately mix a variety of raw materials (such as water, sugar, vitamins, electrolytes, caffeine, plant extracts, etc.) in an automated or semi-automated manner to produce functional beverages that meet specific formulas and standards.

4.Bottle unscrambler:

Automatic bottle sorting

Disorderly sorting: Automatically sort the disordered bottles (such as stacked, fallen or inconsistently oriented) into a uniform direction (such as bottle mouth facing up) and arrange them in order.

Sorting and screening: Remove bottles that do not meet the specifications (such as broken, deformed or inconsistent in size).

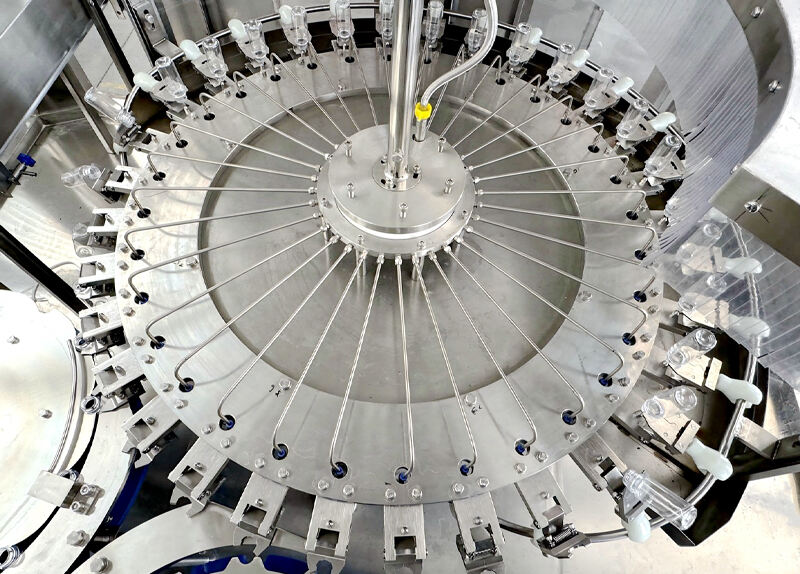

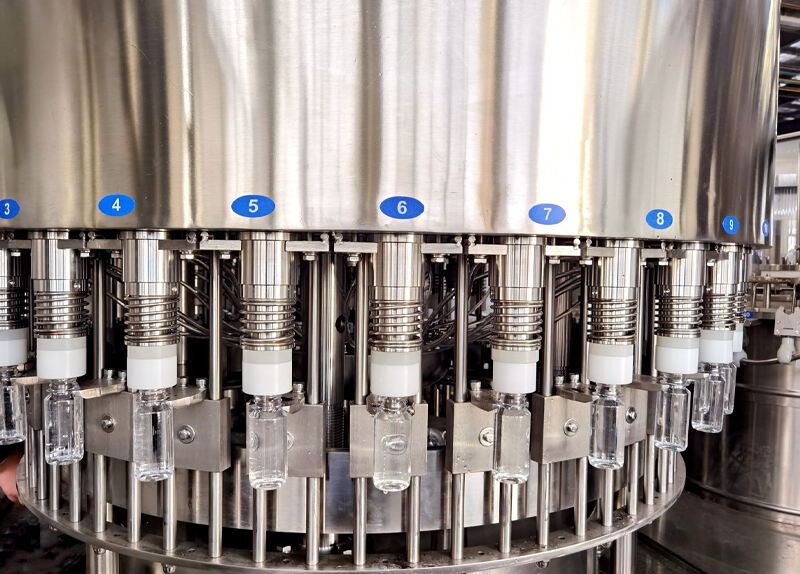

5.Filling System:

Reasonable machine structure

Much higher output

High-efficiency rinsing-nozzles;

Corrosion-resistant bearings from NSK or SKF;

Mechanical valve filling, flow meter filling, weighing filling or laser positioning filling for choice;

Open design for gear transmission;

Siemens PLC & Danfoss VFD & ABB Main motor;

French "ZALKIN" capping technology is used forhigher performance;

Finest bench-working in Chinese Packaging Machinery Industry

Air Conveyor

Bottle infeed

Rinser

Filler

Filling Part

Washing-filling-capping 3 In 1

Liquid Nitrogen Filling Machine

Capper

Finished Product

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

6.Labeling Machine

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, self adhesive labeling machine and OPP hot glue labeling machine.

7.Packaging Machine

There are mainly two kinds of case packing machines, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.