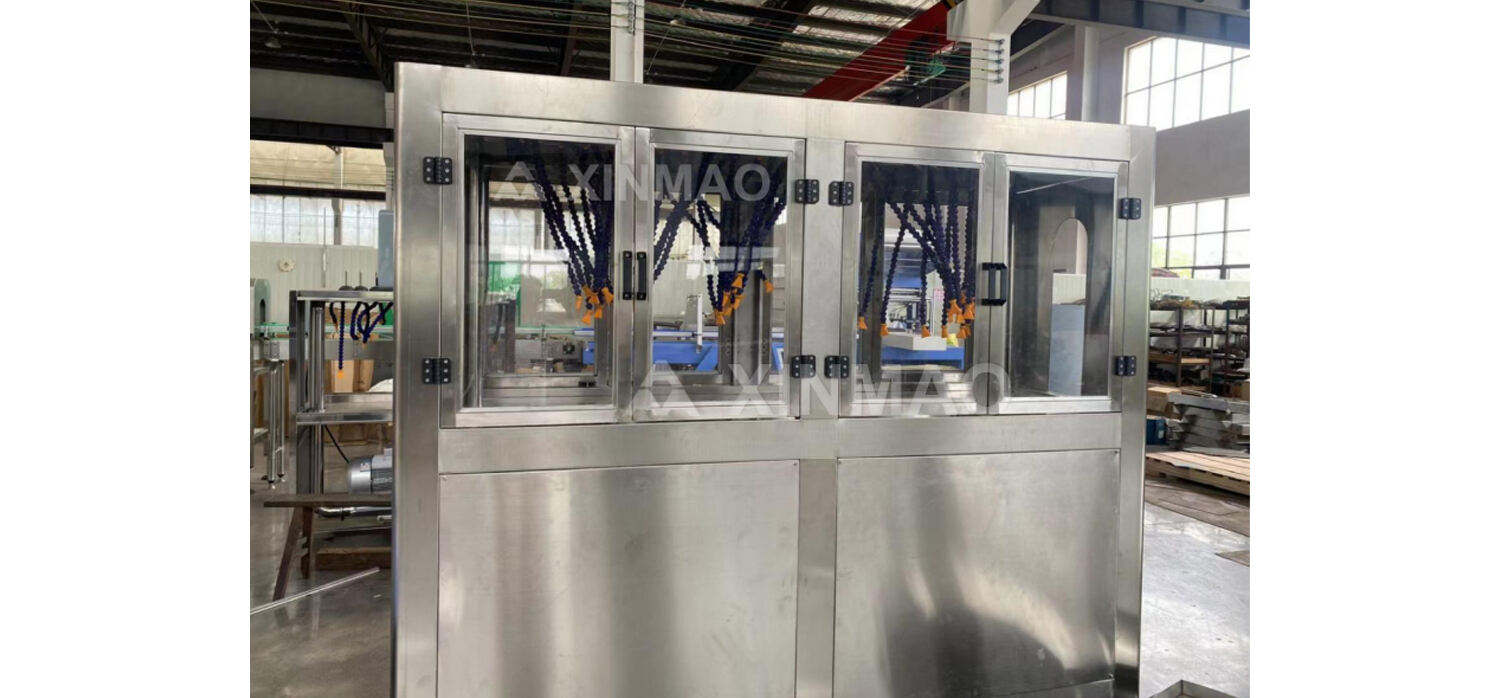

XINMAO DCGF series is special for carbonated soft drinks, soda water, oxygen / hydrogen rich water, energy drinks filling, with rinsing, filling and capping. It is innovated and designed in the requirement of carbonated beverage technology, on the bases of introducing, digesting and absorbing advanced technology abroad. It is reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for beverage producers.

Application : Carbonated drinks, soft drinks, sparkling water, soda water, energy drinks, kvass, beer

Suitable for: Glass Bottle

Bottle sizes:Within 2L

Filling system: Isobaric

Filling speed: 2,000 - 24,000BPH (500ml)

Function :Rinsing Filling Capping Machine

XINMAO DCGF-series rinsing, filling, Capping 3-in-1 monoblock machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

PREPARATION SYSTEM(WATER TREATMENT SYSTEM+BLENDING SYSTEM)

1.Water Treatment System

Applicable water source: Well water, underground water, tap water, river water, spring water, mountain water, etc.

Treated water kind: Pure water, still water, mineral water, alkaline water, etc.

Core filtration equipment: Reverse Osmosis or hollow ultrafiltration.

Electricity control system: Germany Siemens PLC

Treated the raw water into drinkable water.(Customized according to customer water quality)

2.Blending System

Beverage mixing is an art. By combining different ingredients and adjusting the proportions, a rich variety of drinks can be created.

3.Drinks Mixer

Automatic Carbonated beverage mixing system with reasonable & high efficiency structure , high mix precision , CO2 mixing fully, two stage of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing and carbonation, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

This beverage mixer for the production of all kinds of carbonated beverage, (water, syrup, carbon dioxide) of carbonated proportions, such as lemon, cola, fruit juice and other soft drinks, beverage production line equipment is the main equipment. (Inparticular, the high-grade key beverage production equipment)

1 The machine with a chemical industry advanced technology - static mixer (ie carbonizer), its gas-liquid mass transfer area is large, small pressure loss, high efficiency, low energy consumption, simple structure, reliable performance and the use of noise small multi-stage centrifugal pumps, so that the whole performance is guaranteed;

2 Mixing ratio accurate, easy to adjust, the machine does not require replacement parts, you can easily yield and the ratio of syrup and water was adjusted;

3 Reflow machine uses carbon dioxide oxygen, carbon dioxide gas can save, but also to achieve the purpose of deoxy make deoxygenated water has a good pre-carbonization effect;

4 The machine easily adjust the air content, according to the requirements of beverage containing gas through proper operation and adjustment is completed;

5 The machine set up perfect automatic control system with motor coordination, simple structure, continuous production, automation features.

4.Filling System

XINMAO DCGF-series rinsing, filling, Capping 3-in-1 monobloc machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

Rinser

Filler

Capper

The electrical cabinet is made of stainless steel. From bottle infeed to bottle discharge, a PLC controls the fully automatic operation of the 3-in-1 Unit.

| Main Configuration | |

| Touch screen | Siemens |

| PLC | |

| Frequency inverter | |

| Material of flling valve | Stainless steel 304/316 |

| Pneumatic components | Festo |

| Photocell switch | Sick |

| Proximity switch | Sick |

| Motor | SEW |

5.Bottle Warming Machine

Automatic Carbonated beverage mixing system with reasonable & high efficiency structure , high mix precision , CO2 mixing fully, two stage of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing and carbonation, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

This beverage mixer for the production of all kinds of carbonated beverage, (water, syrup, carbon dioxide) of carbonated proportions, such as lemon, cola, fruit juice and other soft drinks, beverage production line equipment is the main equipment. (Inparticular, the high-grade key beverage production equipment)

1 The machine with a chemical industry advanced technology - static mixer (ie carbonizer), its gas-liquid mass transfer area is large, small pressure loss, high efficiency, low energy consumption, simple structure, reliable performance and the use of noise small multi-stage centrifugal pumps, so that the whole performance is guaranteed;

2 Mixing ratio accurate, easy to adjust, the machine does not require replacement parts, you can easily yield and the ratio of syrup and water was adjusted;

3 Reflow machine uses carbon dioxide oxygen, carbon dioxide gas can save, but also to achieve the purpose of deoxy make deoxygenated water has a good pre-carbonization effect;

4 The machine easily adjust the air content, according to the requirements of beverage containing gas through proper operation and adjustment is completed;

5 The machine set up perfect automatic control system with motor coordination, simple structure, continuous production, automation features.

6.Bottle Blow Dryer

A high-pressure fan is used to blow air, so that high-speed air is ejected from the nozzle, so that the water droplets on the bottle body are blown away as much as possible. The nozzle position can be freely adjusted according to the bottle height.

7.Full-Auto OPP Hot Melt Labeling Machine

Opp hot melt labeling machine has great advantages in labeling speed and efficiency, and the later consumables are relatively cheap. It is mostly suitable for carbonated beverage.

8.Full-Auto Packing System

Common capacity range: 8-45 pack/min

Packing Material: LDPE filmPacking method: Film wrapping and shrinking

Shrinking method: By electricity heating

Automation degree: Fully automatic