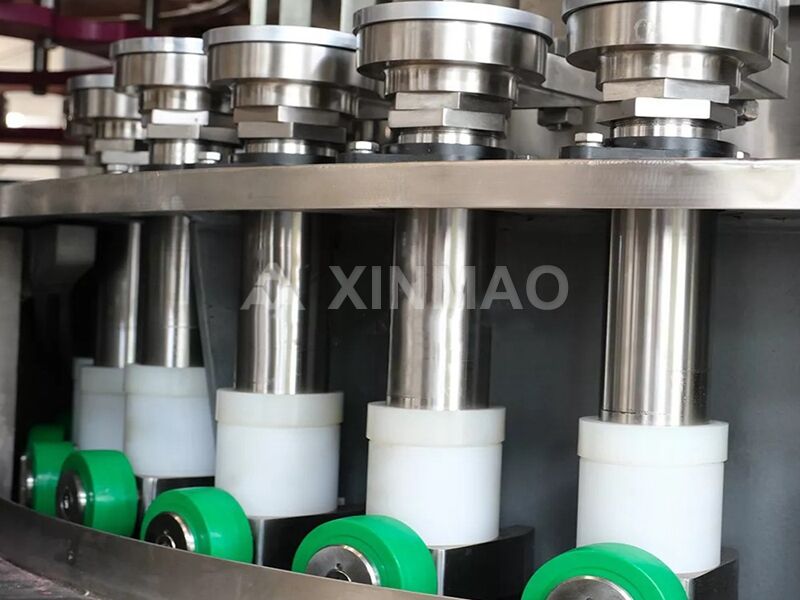

Pastrarea unei mentenări corecte a unei mașini de umplere a sticlelor din sticlă de la ZHANGJIAGANG CITY XINMAO DRINK MACHINERY CO., LTD. este esențială pentru performanța și fiabilitatea sa pe termen lung. Curățați cu regulare toate părțile mașinii, în special valorile de umplere, benzele de transport și capetele de inchidere. Folosiți agenți de curățare adecvați și urmați indicațiile producătorului privind demontarea și remontarea componentelor pentru a evita avaria. Pentru mașinile dotate cu sisteme CIP, efectuați cicluri de curățare rutine cu respectarea programului pentru a preveni depunerea de reziduuri și bacterii. Inspectați în mod regulat închisorile, jantetele și inelele O pentru semne de uzurare sau avarie, și înlocuiți-le imediat pentru a menține o operațiune ermetică și fără scurgeri. Ungurați părțile mobile, cum ar fi rotoarele și lănurile, cu unguitoare recomandate la intervale specificate pentru a reduce frecția și a preveni uzurarea prematură. De asemenea, calibrați cu regulare sistemul de control al volumului de umplere și senzorii de presiune pentru a asigura o umplere precisă și consistentă. Verificați periodic componentele electrice pentru conexiuni strâns sau semne de dysfuncționare, și faceți ca un tehnician profesionist să efectueze mentenanța preventivă și inspecțiile cel puțin o dată pe an.