विभिन्न बोतल प्रकारों और आकारों के लिए सही गैसीय जल बोतलीकरण लाइन का चयन। गैसीय जल की वैश्विक स्तर पर लोकप्रियता बढ़ रही है, जिससे यह प्रीमियम और दैनिक उपभोक्ता बाज़ारों दोनों में एक आवश्यक पेय बन गया है। उपभोक्ताओं की मांग के अनुसार...

अधिक देखें

शुद्ध जल भरण मशीन खरीद मार्गदर्शिका: हज़ारों निर्माताओं और जटिल तकनीकी पैरामीटरों के सामने एक जल कंपनी ने अंततः एक एकीकृत समाधान का चयन किया जिसमें जल... के साथ-साथ अन्य घटकों का समावेश था

अधिक देखें

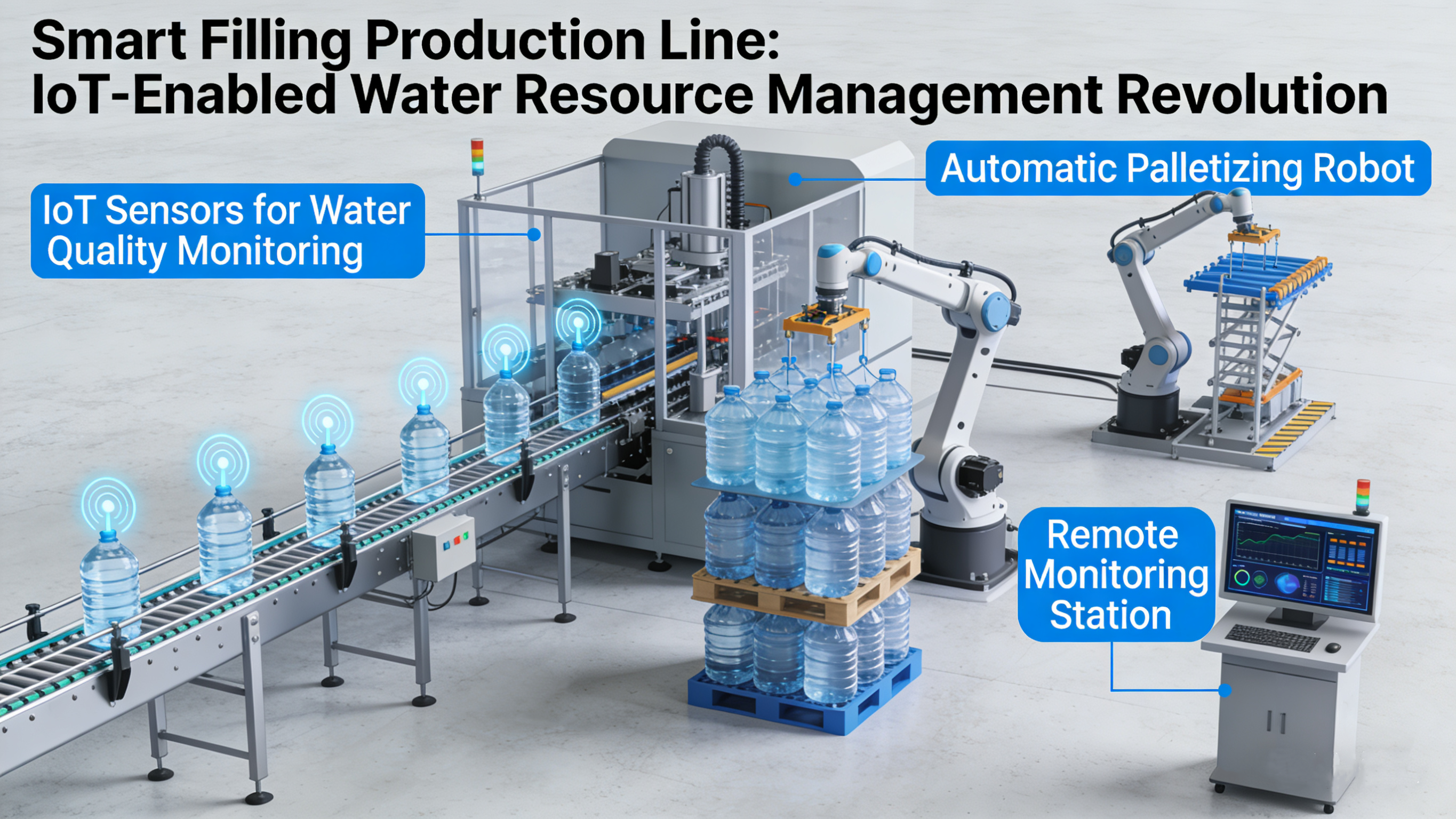

आज के दुनिया में, जहाँ जल संसाधन लगातार कम हो रहे हैं और उपभोक्ताओं की उत्पाद गुणवत्ता के प्रति मांग बढ़ रही है, पारंपरिक बोतलबंद जल उत्पादन मॉडल अभूतपूर्व चुनौतियों का सामना कर रहे हैं। एक ओर, मैनुअल रूप से संचालित उत्पादन लाइनें अक्षम हैं, प...

अधिक देखें

परिचय: समय के दबाव और अवसरों का सामना करना। चीन में कई पारंपरिक बोतलबंद पानी के संयंत्रों में प्रवेश करने पर आपको एक परिचित दृश्य दिखाई देगा: पानी की बोतलबंद उत्पादन लाइनें, जो १५ या यहाँ तक कि २० वर्षों से अधिक समय से सेवा में हैं, अभी भी...

अधिक देखें

सॉफ्ट ड्रिंक भरने की मशीनों में परिशुद्ध कार्बोनेशन नियंत्रण: सॉफ्ट ड्रिंक की ताजगी को बनाए रखने और शेल्फ लाइफ को बढ़ाने के लिए सटीक कार्बोनेशन स्तर बनाए रखना अत्यंत महत्वपूर्ण है। आधुनिक सॉफ्ट ड्रिंक भरने की मशीनें यह कार्य आइसोबैरिक दबाव संतुलन के माध्यम से प्राप्त करती हैं...

अधिक देखें

ग्लास बोतल भरने की मशीनों के लिए दैनिक सफाई प्रोटोकॉल: पेय पदार्थ निर्माण के दौरान सूक्ष्मजीवों के विकास को रोकने और दूषण को रोकने के लिए कड़े दैनिक सफाई दिशानिर्देशों का पालन करना आवश्यक है। इस प्रक्रिया की शुरुआत गर्म पानी से अच्छी तरह से कुल्ला करने के साथ की जानी चाहिए...

अधिक देखें

वॉटर बोतल भरने की मशीनें कैसे काम करती हैं: मूल सिद्धांत और संचालन तर्क — गुरुत्वाकर्षण, दबाव और आयतनिक भरण विधियाँ समझाई गईं: अधिकांश वॉटर बोतल भरने की मशीनें तीन प्रमुख दृष्टिकोणों में से एक — गुरुत्वाकर्षण, दबाव या आयतनिक भरण — का उपयोग करके काम करती हैं...

अधिक देखें

पानी की बोतल भरण मशीन प्रणाली के प्रमुख घटक बोतल हैंडलिंग: अनस्क्रैम्बलर्स, रिन्स स्टेशन और प्रिसिजन कन्वेयर्स आज के पानी की बोतल भरण संचालन उन्नत बोतल हैंडलिंग प्रणालियों पर काफी हद तक निर्भर करते हैं जो सब कुछ सुचारू रूप से चलाए रखती हैं...

अधिक देखें

जूस भरण मशीनें कैसे काम करती हैं: मुख्य सिद्धांत और प्रमुख चयन मापदंड। आधुनिक जूस भरण उपकरण तीन प्रमुख विधियों—गुरुत्वाकर्षण, दबाव और निर्वात प्रणालियों—के माध्यम से तरल को कंटेनरों में सटीक और सुरक्षित रूप से स्थानांतरित करने की गारंटी देते हैं। गुरुत्वाकर्षण...

अधिक देखें

कैसे पेय भरण मशीन प्रौद्योगिकियाँ तरल गुणों और उत्पादन आवश्यकताओं के अनुकूल होती हैं: कार्बोनेटेड, शामिल (स्टिल) और श्यान पेयों के लिए दबाव, गुरुत्वाकर्षण और प्रतिदबाव भरण। आज की भरण प्रणालियाँ विभिन्न प्रकार के तरलों के अनुसार अनुकूलित विशिष्ट प्रौद्योगिकी समाधानों का उपयोग करती हैं...

अधिक देखें

क्यों मोनोब्लॉक बोतल भरण मशीनें लाइन दक्षता में उत्कृष्ट प्रदर्शन करती हैं: एकल-फ्रेम एकीकरण के माध्यम से स्थानांतरण देरी और बोटलनेक को समाप्त करना। मोनोब्लॉक बोतल भरण प्रणालियाँ सफाई से लेकर भरण तक और फिर सीलिंग तक पूरी प्रक्रिया को एक साथ लाती हैं...

अधिक देखें

जल बोतल भरण मशीनों पर महत्वपूर्ण संपर्क सतहों का दैनिक कीटाणुशोधन। खाद्य-ग्रेड अनुपालन और सूक्ष्मजीव नियंत्रण के लिए कीटाणुशोधन आवश्यकताएँ। संपर्क सतहों को प्रतिदिन साफ रखना खाद्य सुरक्षा मानकों को पूरा करने के लिए पूर्णतः आवश्यक है...

अधिक देखें