Ichimliklar sanoati tez o'zgarayotgan bo'lib, yetakchilik qilmoqchi bo'lgan kompaniyalarga faqat yangi g'oyalardan ko'ra narsa kerak bo'ladi. Ular iste'molchilarning xohishlariga hamda bozorlarning kelajakdagi talablariga javob bera oladigan ishonchli texnologiyalarga muhtoj. Zamonaviy to'ldirish tizimlari shu bosimlarga duch kelayotgan ishlab chiqaruvchilar uchun kerakli jixozga aylandi. Bu tizimlar ishlab chiqarishni soddalashtirishda, chiqindilarni kamaytirishda hamda noaniq bozorda narsalarning o'zgarishiga moslashish imkonini beradi. Shunday texnologiyalarni biznes qanday qilib umumiy rejalari ichiga jamlashini o'rganish esa taxminiy bozorda kelajakka tayyorgarlik to'g'risida muhim xulosalarga olib keladi.

Kengaytirilgan Ichimliklarni To'ldirish Yechimlari uchun Talabni Tushunarli Bo'lish

Koʻp bilan shirin ichimliklarni toʻldirishdagi muammolar

Zamonaviy ishlab chiqarish ehtiyojlarini qondirish uchun eski maktab ichimlik to'ldirish usullari endi mos kelmaydi. Qadimiy mexanizmlardan foydalanayotgan kompaniyalar juda ko'p muammolarga duch keladi: natijada juda ko'p mahsulotlar yo'qoladi, qimmatga tushadigan ta'mirlashlarni talab qiluvchi doimiy uzilishlar sodir bo'ladi va asosan zamonaviy mijozlar so'ragan narsalarga javob bera olmaydi. Ishlab chiqarish liniyalari moslashuvchanlikka ega bo'lmasa, bizneslar pul ishlashdan mahrum bo'ladi. Shu sababli, tez o'zgaruvchi bozor sharoitlariga mos keladigan yangi texnologiyalarga o'tishni boshlagan ishlab chiqaruvchilar soni ortib bormoqda.

Teknologiya moddiy ichimliklarni ishlab chiqarishdagi rolidan

Texnologiya bugungi kunda ichimliklar ishlab chiqarishni yaxshilashda katta rol o'ynaydi. Ishlab chiqaruvchilar endi aqlli sensorlar va avtomatlashtirilgan jihozlarni ishlatishni boshladilar. Bu vositalar ishlab chiqarish jarayonida kelib chiqadigan muammolarni vaqtida aniqlashga yordam beradi va operatsiyalarni siliq bajarishda, xatolarni kamaytirishda yordam beradi. Masalan, rivojlangan monitoring tizimlari idishlardagi darajani doim nazorat qilish orqali narsalarning noto'g'ri ketayotganini katta muammo bo'lib ketishidan oldin aniqlab beradi. Bunday aniqlik muhim, chunki iste'molchilar ichimliklaridan doimiy sifat talab qiladilar: siz avtomatdan gazlangan suv sotib olsangiz ham, pubda mahalliy biror pivoni buyurtma qilsangiz ham.

Soddalashtirilgan to'ldirish yechimlariidan foydalar

Yangi to'ldirish yechimlarining afzalliklari bevosita kompaniyaning foydasiga o'tadi. Bu tizimlar ishlab chiqarish tezligini oshiradi, har bir to'ldirishni aniq qiladi, chiqindilarni kamaytiradi va operatsiyalarni umumiy holda tozaroq qiladi. Aqlli moslashuvchan to'ldirish texnologiyasiga investitsiya qilgan kompaniyalarda nima sodir bo'lishini ko'ring. Ular birgaqdan bozor o'zgarishiga tez moslashish imkonini oladi. Masalan, ishlab chiqaruvchi standart o'lchamdagi idishlardan bir necha soat ichida, kunlar emas, balki butunlay boshqa narsaga o'tishi mumkin. Bunday moslashuvchanlik yangi mahsulot formatlari yoki maxsus buyurtmalar bilan tajriba o'tkazishga imkon beradi, qayta sozlash uchun butun liniyani to'xtatmasdan ham.

Muhimroq ichimliklarni to'ldirish texnologiyalari asosiy xususiyatlari

Adaptiv to'ldirish tizimlari

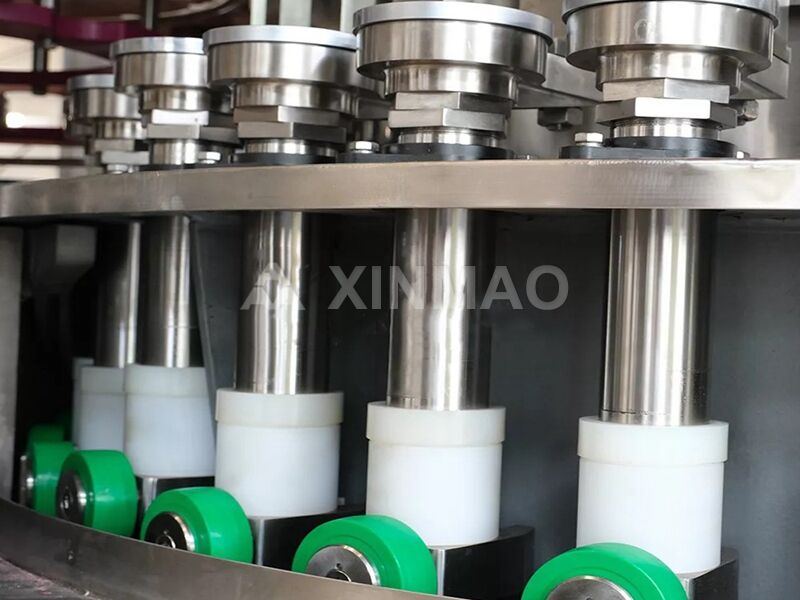

Muhimroq ichimliklarni to'ldirish texnologiyalari turli ishlab chiqarish talablariga moslashuvchan tizimlarga ega. Ushbu tizimlar konteyner hajmini va to'ldirish hajmini farqlashga oson ravishda yo'naltiradi, bu esa ishlab chiqaruvchilarning bir necha mashinalarga pul sarflamadan mahsulotlarni turdagi ko'plab turarini ta'minlaydi.

To'ldirishda aniqlik va aniqlilik

Tochniy texnologiyalar integratsiyasi to'ldirish miqdorining qonunlar bilan mos kelishi va maximalla mahsulot yo'qotilishi kamayishiiga isbot etilgan. Vazn yoki tezlik miqdorlari kabi usullar aniq o'lchovni ta'minlaydi, har bir konteyner uchun optimal to'ldirishni amalga oshiradi va foydalanuvchi qonuniyligini va xaridorlarning qadrlashini yaxshilaydi.

Kengaytirilgan gigiena standartlari

Ichimliklar biznesida narsalarni tozalashni saqlab turish, agar kompaniyalar mahsulotlarini xavfsiz saqlab, mijozlarning ishonchini o'zida ushlab turmoqchi bo'lsa, mutlako zarurdir. Zamonaviy to'ldirish uskunalari tozalash (CIP) operatsiyalari uchun mo'ljallangan maxsus xususiyatlarga ega, ya'ni inshootlar barcha narsalarni to'liq to'xtatmasdan yoki ishlab chiqarishni to'xtatmasdan ham mashinalarni chuqur tozalash imkoniyatiga ega. Tozalikka e'tibor qaratish endi faqatgina qoidalariga rioya qilishdan ham ortiq. Ishlab chiqaruvchilar jarayonlarning barcha bosqichlarida gigiyenaga e'tibor qaratganda, ular aslida o'z brendi tasvirini ham himoya qilmoqda. Sifat bilan bog'liq muammolari bor kompaniyadan ichimlik sotib olishni hech kim xohlamaydi, shu sababli butun etkazib berish zanjirida mahsulot bir xil bo'lishini saqlab turish eng muhim g'amxo'rlik obyekti bo'lib qolmoqda.

Sizning biznesingizni kelajakka tayyorlovchi yoshidigan to'ldirish yechimlari

Operatsion effektivlikning oshishi

Avtomatikasining kengaytirilishi bilan, ko'proq ichimlik ishlab chiqaruvchilari operatsion effektivlikda oshishni his qilmoqda. Haqiqiy vaqtda o'ylab, moslashuvchan bo'lgan jihozlar jarayonlarni optimallashtirishga yordam beradi va nihoyatda resurslarni boshqarish va xarajatlarni kamaytirishga olib keladi. Bu texnologiyalardan foydalanadigan bizneslar, kerak bo'lganda operatsiyalarini skailash uchun yaxshi pozitsiyada turadi.

Mijozlar tomonidan shaxsiylashtirilgan savollar yetkazilishi talabiga javob berish

Bugungi iste'molchilar shaxsiy tajriba va moslashtirilgan mahsulotlarni qidirishadi. Zamonaviy to'ldirish yechimlari ishlab chiqarish jarayonlarida moslikni ta'minlaydi va biznesga o'zgarayotgan iste'molchilar afzalliklariga tez javob berish imkonini beradi. Mahsulot miqdorini, ta'mini yoki qadoqlash uslubini katta uzilishlarsiz o'zgartirish orqali kompaniyalar o'zgarayotgan bozor talablari sharoitida rivojlanishlari mumkin.

Eko-texnik vaorta-muhitga qarama-qarashli praktikalar

Ekologik muammolarga qarago, kompaniyalar o'z ish faoliyatlarini tabiiy hayotni saqlashga qaramasdan rivojlantirish shartiga ega. Jahon miqyosida ishlatiladigan to'ldirish texnologiyalari ekologik materiallardan foydalanadi va energiya tekisligini kamaytiradi, shuning uchun resurslarni saqlashga yordam beradi. Bu esa mijozlarning ekologik mahsulotlarga qaragan rozi bo'lishini ta'minlaydi va ichimlik brendlari ekologik ravishda fikrlab turadigan sotuvchilarga murojaat qilish imkoniyatini beradi.

Amaliy mashg'ulotlar: Jahon miqyosida muvaffaqiyatli ravishda amalga oshirilgan to'ldirish texnologiyalari

Sanoat rejalari jahon miqyosida muvaffaqiyatli yechimlarga ega

Bir necha sanoat rejalari jahon miqyosida muvaffaqiyatli ravishda to'ldirish tizimlarini integrallashtirdi va buni natijada ko'rsatmalarining ayniqsa oshishi bilan bog'liq hisoblagan. Turli xil amaliy mashg'ulotlarda tashkilotlar to'ldirish xatoliklarining kamayishi, ishlab chiqarish tezligining oshishi va operatsion sinovlarning oshishi haqida hisobot beradi.

Efeksiyatlilikning avvalgi va keyingi amaliy mashg'ulotlarini solishtirish

Klassik to'ldirish yechimlaridan modernga o'tgan kompaniyalar uslubiy efeksiyani oshirganini tasdiqladi. Ma'lumotlar ko'rsatadiki, ish jarayonlari kamroq to'xtatilgan, bu esa jamoalarining mahsulotlikiga pozitiv ta'sir ko'rsatdi va nihoyatda daromad manbalarini oshirdi.

Ichimliklarni to'ldirishning kelajagi: modalar va innovatsiyalar

Avtomatizatsiya ma'ni oshishi

Ichimlik sanoatidagi avtomatlashtirishga qaralash juda shaffof muvofiqatlarni yaratish va qo'llab-quvvatlash xodimlari xarajatlarini pas yigitish imkoniyatini beradi. To'liq ravishda avtomatlashtirilgan to'ldirish tizimlari hali ham murakkablashtirilmoqda va ta'minot zanjirlari jarayonlariga eng yaxshi ravishda inteqrallashtirilmoqda, umumiy mahsulotlikni oshirish uchun.

To'ldirish jarayonlarida IN va ma'lumotlar tahlili integratsiyasi

IN asosida ishlangan tahlillar to'ldirish jarayonlarini optimallashtirishda katta rol o'ynaydi. Ehtiyoj ma'lumotlarini tahlil qilish orqali ishlab chiqaruvchilar tendentsiyalarni aniqlash, kelajak talablarni boshqarish va operatsiyalarini moslashtirish orqali tez o'zgaruvchi bozor bilan birgalikda rivoblikka ega bo'lishlari mumkin.

Рынок талаби гибклик ва экологик уртаварликлуга

Ҳажм алмашувчилар экологик масалаларда ижтимоий фикрлаш учун ошириладиганда, уртаварлик практикалари учун талаб ёрдамчи ривожланган чайлов таркиби кўп пахта ташриф этишга таъсир қилади. Ушбу тенденцияларга муваффақият билан таьмин этишда муваффақиятга эга бўлган брендлар自己成功 учун жойлаштирилади.

Xulosa qilib aytganda, yaxshiroq ichimlik to'ldirish tizimlariga sarmoya kirish faqatgina jihozlarni yangilashdan iborat emas. Bu bizneslarga o'zgaruvchan bozorda uzoq muddatli muvaffaqiyat qozonish imkonini beradi. Mijozlar xohishlari doim o'zgarib tursa va sanoat yangi standartlar belgilab tursa, kompaniyalarning ichimlik ishlab chiqarish sohasida o'z dolzarbliklarini saqlab turish uchun yangi texnologiyalarni qabul qilish zarurati tug'iladi. Zamonaviy yechimlarga o'tish ishlab chiqarish quvvatini oshirish bilan birga, brendlar uchun raqobat afzallikini ham yaratadi. Kelajakda g'oliblar o'zgarishlarga tayyor bo'lgan va takomillashib borayotgan kompaniyalar bo'ladi. Boshqalar yetakchi o'ringa ega bo'lib ketayotganda kutib o'tirishning ma'nosi yo'q.

Mundarija

- Kengaytirilgan Ichimliklarni To'ldirish Yechimlari uchun Talabni Tushunarli Bo'lish

- Muhimroq ichimliklarni to'ldirish texnologiyalari asosiy xususiyatlari

- Sizning biznesingizni kelajakka tayyorlovchi yoshidigan to'ldirish yechimlari

- Amaliy mashg'ulotlar: Jahon miqyosida muvaffaqiyatli ravishda amalga oshirilgan to'ldirish texnologiyalari

- Ichimliklarni to'ldirishning kelajagi: modalar va innovatsiyalar