Modern İçecek Üretiminde Dolum Makinesinin Merkezi Rolü

Otomatik Üretim Hatlarının Merkezi Olarak Dolum Makinesini Anlamak

Dolum makineleri günümüzde içecek üretim tesislerinde vazgeçilmez ekipman haline gelmiştir. Birçok işlemi, kapların doldurulmasından kapak ve etiket uygulamalarına hatta temel kalite kontrollerine kadar tek bir akış içinde gerçekleştirirler. Günümüzün çoğu modern hattı doğrudan konveyör bantlara bağlanır ve üreticilerin sürekli bahsettiği o gelişmiş PLC kontrolcülerle birlikte çalışır. Bu entegrasyon, gereksiz gecikmeler yaşanmadan işlerin sorunsuz ilerlemesini sağlar. XYZ Juices'i bir vaka çalışması olarak ele alalım: geçen yıl tam otomatik bir dolum sistemi kurduklarında günlük üretimlerinde neredeyse %27'lik bir artış yaşadılar. Ana fayda nedir? Fabrika zemininde ayrı ayrı makinelerin yer kapma mücadelesi yerine, birden fazla adımı tek bir merkezi noktadan kontrol edebildiğiniz için her şey daha hızlı yapılır.

Manuelden Tam Otomatik Sistemlere: Dolum Sistemlerinin Evrimi

Eskiden şişe doldurma işlemi tamamen elle yapılırdı. Makineler ortaya çıkmadan önce on beş işçi saatte yaklaşık 200 şişe doldurabiliyordu. Bugün ise yalnızca üç kişinin operasyonu denetlediği, saatte 24.000 birim üreten tam otomatik üretim hatları görüyoruz. Bu sıçrama, servo motor teknolojisindeki gelişmeler ve daha iyi optik sensörler sayesinde gerçekleşti. Bu gelişmeler, fabrikaların kalite kontrolünü kaybetmeden üretim kapasitelerini artırmasını sağlıyor. Günümüzün imalat sistemleri, kapalı döngü otomasyon sistemleri sayesinde bu inanılmaz hızlara ulaşmaktadır. Bu durum, insan kaynaklı hataları azaltır ve parti партиler arasında ürün kalitesinin tutarlı olmasını sağlar; bu da rekabetçi pazarlarda itibarlarını korumak isteyen şirketler için hayati öneme sahiptir.

Şişeleme Makinelerinin İçecek Üretiminde Verimliliği Nasıl Artırdığı

Dolgu doğruluğunu artı eksi yüzde yarısında tutmak şişeleme makinelerinin, insanların el ile yaptıklarından çok daha az ürün atması anlamına gelir. Toplamda 18 ila 22% daha az kayıptan bahsediyoruz. Gazlı içecekler için önemli olan, bu makinelerin doldurma sırasında basıncı nasıl idare ettiği. Gerçek zamanlı olarak telafi ediyorlar böylece gazlı içecekler kabarcıklarını sağlam tutar, bu da müşterilerin beklediği özgün parıltıyı korumak için kesinlikle kritik bir şeydir. Sadece atılan ürünlere tasarruf etmenin ötesinde, bu tür bir hassasiyet üreticilerin yeşil hedeflerine ulaşmalarına da yardımcı oluyor. Daha az kayıp ve daha iyi kontrol ile şirketler, tasarruf edilen kaynakları sürekli olarak verimsizliklerin peşinde koşmak yerine yeni ürünler geliştirmeye veya mevcut süreçleri düzeltmeye yönlendirebilirler.

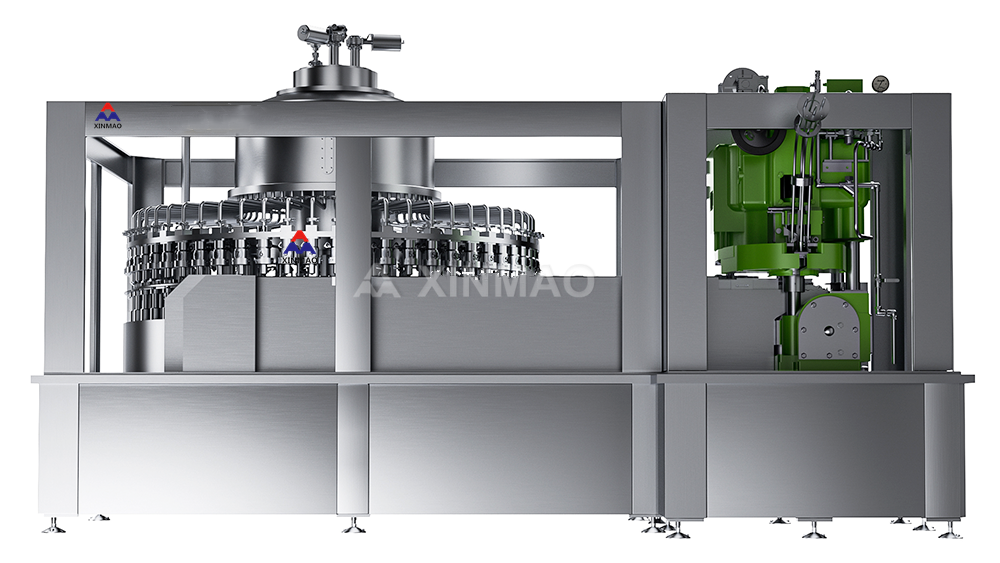

Şişeleme Makinesi'nin Ana Bileşenleri ve Entegre İş Akışı

Şişelenme Süresinin Temel Aşamaları: Doldurma, Kaplama, Etiketleme ve Kalite Kontrolü

Günümüzün şişeleme makineleri, üretim boyunca tutarlı kaliteyi korumaya yardımcı olan dört ana işlevi bir araya getirir. Doldurma işlemleri için, üreticiler genellikle hacim ölçümlerine, yerçekimi beslenen sistemlere veya basınç tabanlı yaklaşımlara dayanırlar, bunların hepsi de israf edilen ürünü azaltmak için yaklaşık yüzde yarım doğruluğa yöneliktir. Kaplama kaplama teknolojisi, su geçirmez mühürler oluşturmak için kontrol edilen tork kullanır. Bazı daha iyi sistemler, işledikleri neredeyse her şişede sızıntıları önlemeyi başarıyor. Etiketleme istasyonları da oldukça gelişmiş hale geldi. Etiketleri yaklaşık 10'un ikinci milimetre doğruluğunda konumlandırmak için optik sensörler kullanıyorlar. Böylece markalar mağaza raflarında profesyonel görünüyor. Kalite kontrolleri, her dakika yüzlerce şişeyi herhangi bir kusur arayan görsel denetim sistemleri aracılığıyla gerçekleşir. 2023'te İçecek Üretimi'nden yapılan son bir rapor, bu tamamen entegre hatların, daha eski manuel yöntemlerle karşılaştırıldığında paketlendikten sonra reddedilen ürünleri neredeyse üçte iki oranında azaldığını gösterdi.

Kesintisiz çalışma için taşıyıcıların, PLC'lerin ve besleyici sistemlerin entegrasyonu

Şişeleme makinelerinin güvenilirliği senkronize alt sistemlerine bağlıdır:

- Taşıyıcılar akış hızını ve istikrarını dengelemek için en iyi 12-15 ft/min hızları korumak

- PLC'ler (Programlanabilir Mantık Denetleyicileri) 10ms yanıt süresi ile operasyonları koordine etmek

- Besleme sistemleri şişeleri doğru 150 derecelik artışlarla yönlendirmek için servomootor kullanın.

PLC entegre otomasyonu kullanan tesisler, zamanlayıcı tabanlı kontrollere dayananlara göre% 92 daha az duraklama yaşarlar. Modüler tasarımlar ayrıca hızlı değişimlere izin verir 330 ml'lik kutulardan 1 litrelik PET şişelerine geçiş 45 dakikadan az bir sürede tamamlanabilir, bu da esnek üretim sürelerini sağlar.

Kesinlik ve Çözümün Sağlanması İçin Alt Sistemlerin Senkronizasyonu

Bileşenler gerçek zamanlı olarak birbirleriyle konuşurken, şişeleme makineleri toplam ekipman etkinliğinin (OEE) yaklaşık yüzde 95 ila neredeyse yüzde 98'ini koruyabilir. Kodlayıcılar tarafından çalıştırılan dolgu kafaları, taşıyıcı kemer hareketinden ne hissettiğine bağlı olarak akış hızlarını ayarlar. Aynı zamanda, bu kaplama istasyonları bir kaplama boyutundan diğerine geçiyorken ne kadar kuvvet uygulayacağını tam olarak bilirler. Bilgisayar modellerini kullanan bazı son testler oldukça ilginç bir şeyi de gösteriyor. Yan yana kurulan şişeleme hatları, dakikada 600 şişe işleme koyulduğu için, makinelerin sırayla çalıştığı eski sistemlere kıyasla, aslında yaklaşık yüzde 40 daha fazla üretim üretmektedir. Ve bahsetmeye değer bir başka avantaj daha var. Bu senkronize işlemler kalın sıvılardaki rahatsız edici termal genişleme sorunlarını azaltıyor. Geçen yıl Packaging Tech Quarterly'ye göre bu oran yaklaşık yüzde 22 azalmıştı.

Şişeleme Makinesi: Otomatik İçecek Üretim Hatlarının Kalbi

Şişeleme Makinelerinin Türleri ve Uygulamaya Özel Seçimi

Hacimsel, Gravite ve Basınçlı Dolum Makineleri: Nasıl Çalışırlar

Çeşitli dolum yöntemleri, farklı türdeki ürünler için en iyi şekilde çalışır. Hacimsel doldurucular, sıvıları doğru bir şekilde ölçmek için pistonlar veya akış ölçerler kullanır ve bu da şurup veya bal gibi daha yoğun maddeler için ideal hale getirir. Su veya meyve suyu gibi daha ince sıvılar için gravite beslemeli sistemler ürünün makine boyunca doğal olarak akmalarına izin verir ve genellikle artı eksi yüzde yarısında bir doğruluk sağlar. Karbonatlı içecekler söz konusu olduğunda ise değerli CO2 kabarcıklarını korumak—meyveli sodaların kabarcıklı kalması açısından kesinlikle önemli olan bir şey—için 25 ila 35 psi arasında basınç uygulayan basınç tabanlı doldurucular tercih edilir. Sektör araştırmalarına göre, karbonatlı ürünler işlenirken döner basınç doldurucular, normal gravite modellerine kıyasla çevrimlerini yaklaşık %90 daha hızlı tamamlayabilir; bu da fabrikaların aynı sürede çok daha fazla şişe üretebilmesi anlamına gelir.

Makine Tipini Karbonatlı ve Karbonatsız İçecek İhtiyaçlarına Uydurma

Karbonasyon stabilitesi, ekipman seçimini belirler. Çift mühürlü nozullara sahip basınca duyarlı doldurucular, açık yerçekimi yöntemlerine kıyasla CO2 kaybını en aza indirerek köpük kaynaklı israfı %7'ye varan oranlarda azaltır. Buna karşılık karbonatlı olmayan hatlar, meyve suları ve aromalı sular için dakikada 600 şişeye kadar çıkabilen hat içi hacimsel makinelerle hızı önceliklendirir.

Ölçek, Hız ve Geri Verim'e Bağımlılıktan Doğru Şişeleme Makinesi Seçimi

Otomatik döner dolgu makineleri, günde 10.000'den fazla birim üreten tesislerde yarı otomatik modellerden 2.8 kat daha yüksek ROI sağlar (2023 İçecek Üretimi Raporu). El yapımı bira üreticileri gibi küçük ölçekli üreticiler, %60 daha az ön yatırım gerektiren modüler yerçekimi sistemlerinden yararlanmaktadır. Ana seçim faktörleri şunlardır:

- Geçiş Kapasitesi Gereksinimleri : 200 ila 20.000 şişe/saat arasında değişmektedir

- Ürün viskozluğu : Şuruba genellikle ısıtma ceketleri ile piston dolguları gereklidir

- Gaz tutma ihtiyaçları : PET soda şişelenmesi 3 aşamalı basınçlandırmayı gerektirir

Makine yetenekleri ve üretim parametreleri arasındaki uygun uyum, değişim süresini %40 ve enerji maliyetlerini %18 oranında azaltır.

Otomasyonla Üretimlilik Artışı ve İşçi Maliyetlerinin Düşüşü

Verimliliği Ölçmek: İşletme, Süreklilik ve Atıkların Azaltılması

Üretim verimliliğine gelince, otomasyon gerçekten ne kadar üretildiği, kalitesi ne kadar tutarlı olduğu ve ne kadar az israf edildiği gibi birkaç önemli alanda fark yaratıyor. Örneğin modern şişeleme ekipmanlarını ele alalım. Bu günlerde her iki şekilde de doldurma seviyelerini yüzde yarımın içinde alabilirler, malzeme atıklarını yüzde 17 oranında azaltabilirler ve toplamda yaklaşık yüzde 30 daha fazla ürün üretebilirler. Boston Danışma Grubu'nun 2023'te yaptığı araştırmaya göre, tamamen otomatik sistemlere geçiş yapan şirketler, hala yarı otomatik yöntemleri kullananlara kıyasla işgücü masraflarının yaklaşık üçte birini tasarruf etti. Daha ilginç olan ise, gerçek zamanlı izleme sistemlerinin perde arkasında neler olduğunu, örneğin, taşıyıcıların ne kadar hızlı hareket ettiklerini ve temizlik işlemlerinin doğru şekilde tamamlandığını takip etmeleri, bu da üreticilerin bir vuruşu kaçırmadan operasyonları sürekli olarak ayarlayabilmeleri anlamına geliyor.

Ürün Kayıplarını Minimize Etmek İçin Hassas Dolgu ve Kaplama

Servo tahrikli dolgu makineleri, her hat başına yıllık 740 bin dolar tasarruf edeceği tahmin edilen pahalı aşırı dolguları önleyerek% 99.8 dağıtım doğruluğunu elde eder (Ponemon, 2023). Kaplama sistemlerinde tork doğrulama, mühürleme arızasını %92 azaltır, geri çağırmaları en aza indirerek ve özellikle premium el içecekleri için hayati önem taşıyan FDA standartlarına uygunluğu sağlar.

Vaka Çalışması: Otomasyon sonrası %40 İşgücü Maliyetindeki Düşüş

Güney Amerika'dan büyük bir içecek üreticisi 2022'de akıllı şişeleme teknolojisi uyguladıktan sonra işgücü masraflarını neredeyse %40 oranında düşürdü. Yeni sistem, şişelerin nasıl yerleştirildiğini kontrol etmek ve partilerin izini sürmek gibi sıkıcı işleri devraldı, böylece işçiler bunun yerine ürün kalitesi için gerçekten önemli olan şeylere odaklanabiliyorlardı. Oldukça havalı bir şey de oldu. Yapay zekâ ile her şişeye ne kadar sıvı girdiğini ve kapakların ne kadar sıkı kapatıldığını ayarlamaya başladıklarında üretim sırasında atıkları neredeyse %30 oranında azaltmayı başardılar. Daha az malzeme israfı, iş için daha fazla tasarruf anlamına geldiğinden, mantıklı geliyor.

Akıllı Şişeleme Makineleri: IoT, AI ve Geleceğe Hazır Yenilikler

Akıllı şişeleme sistemlerinde gerçek zamanlı izleme ve veri analizi

IoT'ye sahip şişeleme makineleri, sürekli performans sağlamak için saniyede 150'den fazla veri noktasını toplar. Bu gerçek zamanlı görünürlük, ± 0,5% dolgu doğruluğunu korur ve anında hata tespiti yoluyla arıza süresini% 18 azaltır (Dünya Ekonomik Forumu). Merkezi paneller kullanan tesisler, üretim geçişlerini kolaylaştırarak %22 daha hızlı değişim rapor ediyor.

Yapay zeka ve makine öğrenimi kullanarak öngörüsel bakım

Yapay zeka algoritmaları, bileşen aşınmasını %92 doğrulukla tahmin etmek için tarihsel performansı analiz ederek planlanmamış duraklama süresini %40 azaltır. Makine öğrenimi modelleri, titreşim ve termal verileri birleştirerek, arızalardan 8-12 saat önce rulman arızasını tespit eder. Bu proaktif yaklaşım, ekipman ömrünü geleneksel bakım programlarına kıyasla %25 uzatabilir.

Üretim ve tedarik zinciri boyunca uçtan uca görünürlük için IoT entegrasyonu

Şişeleme makinelerinin IoT geçitleri üzerinden ERP ve envanter sistemlerine bağlanması, malzeme stoklarını %33 ve nakliye hatalarını %19 azaltır. Bulut tabanlı platformlar, gerçek zamanlı perakende talebine dayalı dinamik zamanlamayı sağlar ve pilot programlarda sipariş yerine getirme oranlarını %27 artırır.

Akıllı şişeleme teknolojisinde yüksek ön maliyetlerle uzun vadeli ROI'yi dengeleme

Akıllı şişeleme sistemleri başlangıç yatırımını %30-50 daha fazla gerektirse de, uzun vadede önemli tasarruflar sağlar. Enerji tasarrufuyla tasarlanan tasarımlar, enerji tüketimini yılda %22-35 oranında azaltır. 2024 ROI çalışması, çoğu tesisin atık azaltma ve iyileştirilmiş çalışma süresi yoluyla 2.7 yıl içinde maliyetleri geri kazandığını ve gelişen Endüstri 4.0 standartlarıyla uyumluluğu sağlayan sürekli yazılım güncellemeleri ile bulundu.

Sık Sorulan Sorular (SSS)

Otomatik şişeleme makinelerinin kullanımındaki en önemli faydalar nelerdir?

Otomatik şişeleme makineleri, üretim hızını artırır, işçilik maliyetlerini düşürür, ürün tutarlılığını iyileştirir, atığı azaltır ve genel verimliliği artırır.

Şişeleme makineleri farklı türdeki içecekleri nasıl işler?

Şişeleme makineleri, farklı içecek türlerini işlemek için hacimsel, yerçekimi ve basınç tabanlı gibi çeşitli doldurma yöntemleri kullanır ve gerektiğinde karbonasyonun korunmasını sağlar.

Şişeleme işlemlerinde Toplam Ekipman Etkinliği (OEE) nedir?

OEE, üretimin verimliliğini, verimlilik, kalite ve kullanılabilirlik üzerinde odaklanarak ölçer. Yüksek OEE, şişeleme işlemlerinde daha iyi verimlilik ve daha az durma süresi olduğunu gösterir.

IoT ve AI şişeleme makinelerinin performansını nasıl artırıyor?

IoT ve AI, gerçek zamanlı izleme, öngörüsel bakım ve gelişmiş senkronizasyonu sağlar, aralıklı aralıklı aralıklı aralıklı çalışmayı azaltır, ekipman ömrünü uzatır ve üretim verimliliğini optimize eder.

İçindekiler

- Modern İçecek Üretiminde Dolum Makinesinin Merkezi Rolü

- Şişeleme Makinesi'nin Ana Bileşenleri ve Entegre İş Akışı

- Şişeleme Makinesi: Otomatik İçecek Üretim Hatlarının Kalbi

- Şişeleme Makinelerinin Türleri ve Uygulamaya Özel Seçimi

- Otomasyonla Üretimlilik Artışı ve İşçi Maliyetlerinin Düşüşü

- Akıllı Şişeleme Makineleri: IoT, AI ve Geleceğe Hazır Yenilikler

- Sık Sorulan Sorular (SSS)