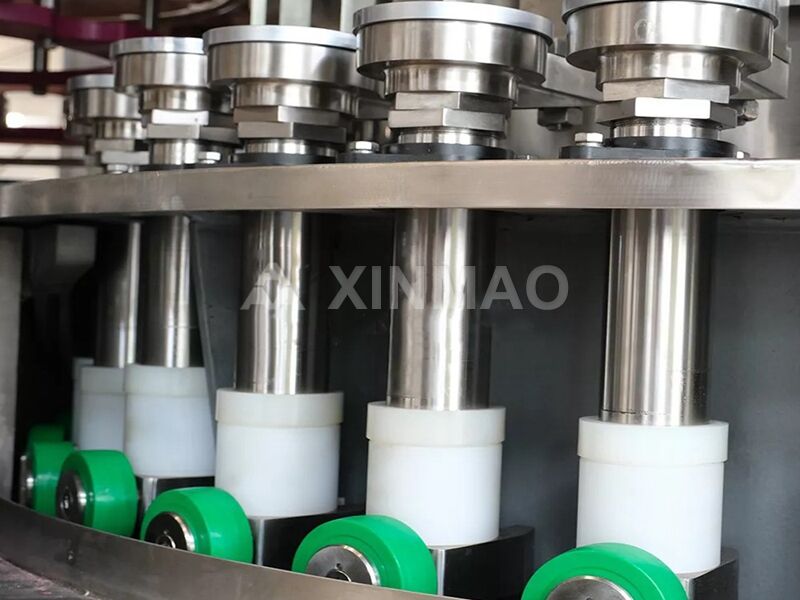

ZHANGJIAGANG CITY XINMAO DRINK MACHINERY CO., LTD-ын бага зэрэг ашиглах пивний дулаан хийх машинууд нь өндөр, стандарт шилэн буталтай бутлуур болон цагаан таслалттай бутлууртай адилхан хэмжээтэй бутлууртай байдаг. Эдгээр машинуудад шилэн буталтай бутлуур, конвейерийн зогсоол, цуглуулагчийн галзуу болон бусад хэсгүүдийг шилжүүлэх боломжтой бөгөөд бутлууртын диаметр (жишээлбэл, 330мл, 500мл, 1Л) хоорондоо хурдан шилжүүлэх боломжтой. Изобарик дулаан хийх систем нь ямар ч бутлуурт харьцуулан угамсан хадгалж байна. Модульчлагдсан дизайны нь шилдэгчид, барих машинууд зэрэг нэмэлт хэсгүүдийг оруулахад зориулан тохирсон бөгөөд эргэлттэй бүтээгдэхүүн боловсруулалтын мөрөөсөө хамаарах боломжтой. Хамгийн их ухаалаг буталтай бутлуур эсвэл алуминийн цагаан таслалтай бутлууртай дулаан хийхэд эдгээр машинууд нь ихээхэн зөвлөх, үнэтэй байдаг тул зөвхөн ялгаатай бүтээгдэхүүнүүдийг ашиглах буузуудад зориулсан байдаг. Таны буталтай бутлууртай холбоотой өөртөө шаардлага бүрийг тохируулах боломжийг олохын тулд бидний төрөл бүрийг холбож магадгүй.