Introduction to Beer Filling Machines

What is a Beer Filling Machine?

A beer filling machine is specialized equipment designed to accurately fill beer bottles or cans in various production environments. These machines are crucial elements in the bottling process and come in several configurations, catering to the needs of different brewery sizes â from small-scale craft breweries to large production facilities.

Importance of Quality in Beer Filling

Quality in beer filling is non-negotiable. The filling process must preserve the beer's flavor and aroma while minimizing exposure to oxygen, which can spoil its quality. A reliable beer filling machine ensures consistent filling volumes, reducing overfills and spillage â ultimately contributing to the maintenance of product integrity.

Benefits of Using a Reliable Beer Filling Machine

Efficiency and Productivity

A good beer filling machine makes all the difference when it comes to scaling up production. These automated systems run fast and accurate, so breweries can keep up with orders while still maintaining their signature taste profile. The latest models come packed with features that speed things along during bottling season. Many small craft brewers report being able to double their output within months after upgrading equipment. Time saved on manual processes means more focus on what really matters brewing great beer consistently.

Consistency in Filling

Every bottle should contain an equal amount of beer. Inconsistent filling can undermine consumer trust and brand reputation. High-quality filling machines are engineered to provide uniform filling, ensuring customers receive the same quantity and quality of product every time.

Minimized Waste and Quality Preservation

In the competitive brewing landscape, waste management is essential. Reliable beer filling machines minimize waste through precise filling and advanced control systems. This efficiency helps preserve the quality of the beer while also maintaining company profits by reducing unnecessary losses.

Key Features to Look for in a Beer Filling Machine

Filling Speed and Capacity

When selecting a beer filling machine, consider its speed and filling capacity. Optimal machines can fill hundreds to thousands of bottles per hour, depending on the scale of your production. Ensure the machine can keep up with your current and projected production needs to avoid potential bottlenecks.

Automation Levels

Picking the right equipment depends on how much automation is needed for brewing operations. Full automation works best when there are hundreds or thousands of barrels being produced each week at big commercial facilities. But many small craft brewers find semi-automated setups work better for their needs since they maintain greater control over the process. The tradeoffs are pretty straightforward really. Automated systems cut down on staffing expenses significantly, which matters a lot for high volume production. On the flip side, semi-auto machines let brewers get their hands dirty during critical stages like fermentation monitoring and quality checks that just cant be left to robots entirely.

Versatile Compatibility with Bottle Sizes

A reliable filling machine should accommodate various bottle sizes and shapes. Whether your brewery uses standard bottles or unique craft containers, having a versatile machine ensures youâre prepared for different packaging demands without needing additional equipment.

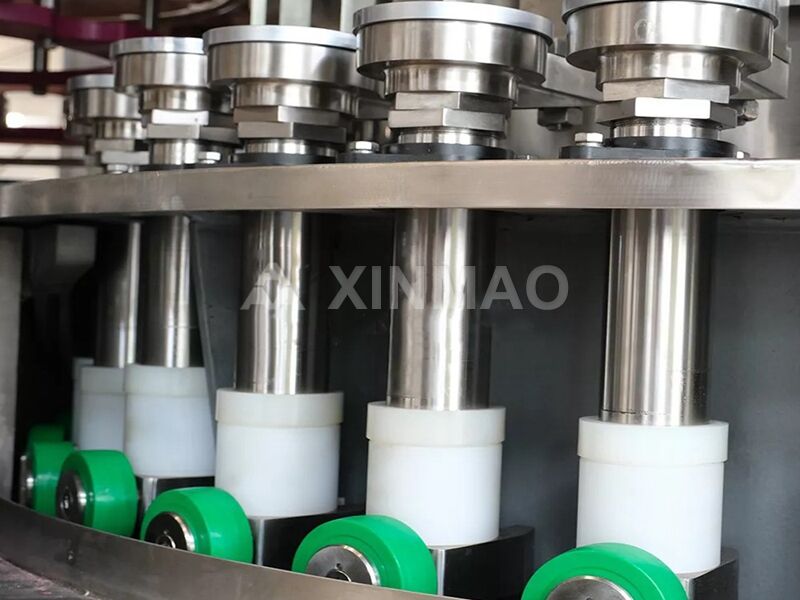

Maintainability and Durability

Beer filling machines are an investment. Therefore, look for models made from high-quality materials that are easy to maintain. Machines that are simple to clean and have longer operational lifespans provide better returns on investment.

Cost Considerations When Investing in Beer Filling Machines

Understanding Initial Investment vs. Long-term Costs

While high-quality beer filling machines can be costly upfront, itâs vital to evaluate their long-term financial benefits. A machine that operates efficiently with minimal maintenance will save money over time, making it essential to consider overall costs rather than just the sticker price.

Evaluating ROI and Budget Constraints

It's crucial to assess your budget thoroughly. Determine how the investment aligns with your production goals and revenue projections. A higher initial investment might be justifiable if it delivers significant efficiency, quality, and productivity improvements.

Conclusion: Choosing the Right Beer Filling Machine for Your Business

Assessing Your Brewing Needs

Take a comprehensive look at your brewing requirements before making a purchase. Understand your production volume, the types of bottles or cans youâll be filling, and your budget constraints. This clarity will guide you toward the right machine to enhance your operations.

Researching and Selecting a Supplier

Choosing the right supplier is also pivotal. Look for manufacturers or distributors with well-established industry reputations. Reading customer testimonials and assessing support services will ensure you receive a filling machine that not only meets but exceeds your expectations.

Investing in a reliable beer filling machine can dramatically improve your brewery's efficiency, quality, and profitability. This strategic decision will aid in scaling up your production without compromising the integrity of your beer. Make the investment today and elevate your brewing process to new heights.