The beverage industry is changing fast, and companies wanting to stay ahead need more than just new ideas. They require reliable tech that keeps pace with what consumers want and what markets demand next. Modern filling systems have become must-have equipment for manufacturers trying to handle these pressures. These systems help streamline production while cutting waste and making it easier to adjust when things change unexpectedly. Looking at how businesses incorporate such technologies into their overall plans reveals important insights about preparing for whatever comes next in an unpredictable marketplace.

Understanding the Need for Advanced Beverage Filling Solutions

Challenges in Traditional Beverage Filling Processes

Old school beverage filling techniques just don't cut it anymore when it comes to keeping up with modern production needs. Companies stuck using ancient machinery face all sorts of headaches including mountains of wasted product, constant breakdowns requiring expensive repairs, and basically being unable to keep pace with what customers want these days. When production lines lack flexibility, businesses end up losing money left and right. That's why we're seeing so many manufacturers making the jump to newer technologies that actually work for today's fast changing market conditions.

The Role of Technology in Modern Beverage Production

Technology plays a big role in making beverage production better these days. Manufacturers are now using things like smart sensors and automated equipment throughout their facilities to keep tabs on what's happening during production runs. These tools help catch problems early and generally make operations run smoother while cutting down on mistakes. For instance, advanced monitoring setups can watch tank levels closely and spot when something isn't quite right before it becomes a bigger issue. This kind of precision matters because consumers expect consistency from their drinks whether they're grabbing a soda from a vending machine or ordering craft beer at a pub.

Benefits of Streamlined Filling Solutions

The advantages of advanced filling solutions go straight to the company's profits. These systems boost production speeds while making sure each fill is accurate, cut down on wasted materials, and keep operations cleaner overall. Take a look at what happens when companies invest in smart adaptive filling tech. They suddenly gain the flexibility to adjust quickly as markets shift. A manufacturer might switch from standard sized containers to something completely different within hours rather than days. This kind of responsiveness lets them experiment with new product formats or special orders without shutting down the whole line for reconfiguration.

Key Features of Advanced Beverage Filling Technologies

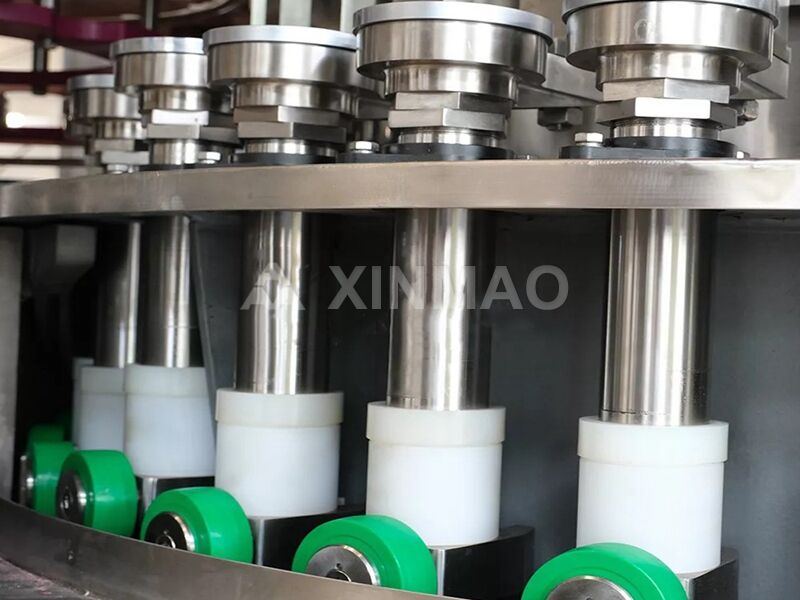

Adaptive Filling Systems

Advanced beverage filling technologies feature adaptive systems capable of adjusting to various production requirements. These systems can seamlessly change settings to accommodate different container sizes and fill volumes, enabling manufacturers to diversify product offerings without investing in multiple machines.

Precision and Accuracy in Filling

The integration of precision technology ensures that filling quantities meet regulations while minimizing product loss. Techniques such as weight or flow metrics allow for precise measuring, resulting in optimal fills for every container, thus improving profitability and customer satisfaction.

Enhanced Hygiene Standards

Keeping things clean is absolutely essential in the beverage business if companies want to keep their products safe and retain customer confidence. Modern filling equipment comes equipped with special features designed for clean-in-place (CIP) operations, which means facilities can sanitize machinery thoroughly without taking everything apart or stopping production completely. The emphasis on cleanliness goes beyond just following regulations these days. When manufacturers prioritize hygiene throughout their processes, they're actually safeguarding their brand image too. Nobody wants to buy drinks from a company known for quality issues, so maintaining product consistency remains a top concern across the entire supply chain.

How Advanced Filling Solutions Can Future-Proof Your Business

Increase in Operational Efficiency

With the increasing adoption of automation, more beverage producers are experiencing enhanced operational efficiency. Equipment that can think and adjust in real-time helps streamline processes, ultimately leading to better resource management and cost efficiency. Businesses that leverage these technologies are better positioned to scale their operations as needed.

Meeting Consumer Demands for Customization

Todayâs consumers seek personalized experiences and customized products. Advanced filling solutions foster flexibility within manufacturing processes, enabling businesses to address evolving consumer preferences swiftly. By adjusting product quantities, flavors, or packaging styles without major disruptions, companies can thrive amidst changing market demands.

Sustainability and Environmentally-Friendly Practices

As sustainability continues to gain traction, companies are under pressure to adopt environmentally responsible practices. Advanced filling solutions often utilize eco-friendly materials and energy-efficient technology, helping reduce waste and conserving resources. This aligns with the growing consumer preference for sustainable products, enabling beverage brands to appeal to environmentally-conscious buyers.

Case Studies: Successful Implementation of Advanced Filling Solutions

Industry Leaders Benefiting from Advanced Solutions

Many industry leaders have successfully integrated advanced filling systems, leading to significant performance metrics improvements. In various case studies, organizations report reductions in filling errors, enhanced production speeds, and increased operational flexibility.

Comparative Analysis of Efficiency Pre- and Post-Implementation

Companies that transitioned from traditional to advanced filling solutions have documented enhanced efficiency. Data indicates that workflows became less interrupted, leading to enhanced team productivity and ultimately resulting in increased revenue streams.

The Future of Beverage Filling: Trends and Innovations

Rising Importance of Automation

The trend towards automation in the beverage industry presents exciting opportunities to streamline operations and reduce manual labor costs. Fully automated filling systems are becoming increasingly sophisticated, integrating seamlessly into supply chain processes to enhance overall productivity.

Integration of AI and Data Analytics in Filling Processes

AI-driven analytics will play a greater role in optimizing filling processes. By analyzing production data, manufacturers can identify trends, predict future demands, and tailor their operations accordingly, ensuring they remain competitive in a rapidly evolving market.

Market Demands for Flexibility and Eco-Sustainability

As consumers exhibit increased awareness of environmental issues, the demand for sustainable practices will significantly influence beverage production. Brands successfully adapting to these trends will find themselves well-positioned for success.

To wrap things up, putting money into better beverage filling systems goes beyond just upgrading equipment. It actually positions businesses for long term success in a changing market. As customers keep shifting what they want and the industry keeps setting new standards, companies need to adopt new tech if they want their beverage operations to stay relevant over years. Going with these modern solutions boosts production capacity for sure, but it also gives brands a real advantage when competing against others. Looking ahead, the winners will be those ready to roll with changes and keep improving. There's no point waiting around while competitors take the lead in this space.

Table of Contents

- Understanding the Need for Advanced Beverage Filling Solutions

- Key Features of Advanced Beverage Filling Technologies

- How Advanced Filling Solutions Can Future-Proof Your Business

- Case Studies: Successful Implementation of Advanced Filling Solutions

- The Future of Beverage Filling: Trends and Innovations